China supplier air duct making machine HAVC ducting auto duct line 5

China supplier air duct making machine HAVC ducting auto duct line 5

- Detail

- Review

- Parameters

China supplier air duct making machine HAVC ducting auto duct line 5

Brief Introduction,

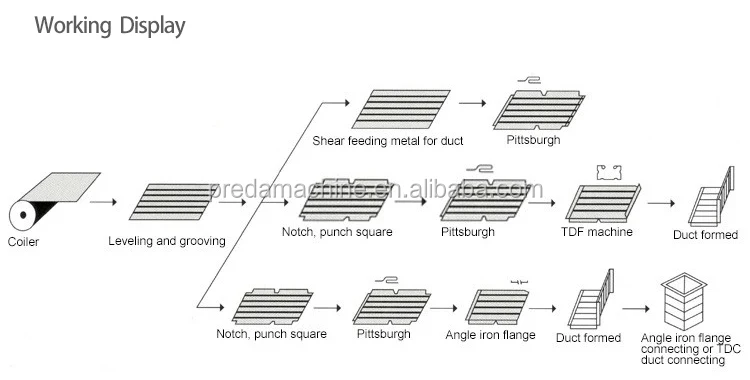

Square Duct Forming auto duct line 5 adopts modular Linear design, with several integrated flexible workstations. Total length of the line is about 18mtrs.

Basic Equipments,

1. Electric uncoiler(two sets) driven by independent frequency controlled motor.

2. Multi-functional machine with capability of levelling,grooving,angle shearing and plate shearing

3. Multi-functional Pittsburgh machine

4. Servo-controlled material transporting table

5. Dual TDF flange forming machine

6. Hydraulic press brake

7. Computer controlling system and softwares.

8. Electric box

Characteristics,

1. Optimized linear structure makes the whole line beautiful in appearance and fast in production

2. 11 rollers are equipped for levelling to make sure plate gets even.

3. This machine is a material-saving facility with only less than 20mm wasted plates per roll.

4. Highly advanced servo system controls the whole production line very well so the products produced are perfect in appearance and precise in size.

5. One man is capable to handle the whole line

6. Workpieces counting system to count for one-day and accumulated quantities.

China supplier air duct making machine HAVC ducting auto duct line 5

Product Description

Auto duct line 5 is a most cost efficient full auto duct forming line with the duct formed automatically from decoiling to a formed squared duct!

Every step could be controlled by putting parameters into Mitsubishi PLC screen.

Having an auto duct line 5 is a magnificent sign of scaled HVAC duct factory in the whole world!

Preda Machine providesthe fastest, most reliable and cost saving Automated Duct Systems Available inoperation in China and worldwide!

Our auto duct line 5 can manage coil to duct "L" sections averaging every 15seconds and a full wrap duct every 30 seconds.

The highest quality, most productive &cost efficient coil line (duct manufacturing) machines nowadays.

It adopts modular Linear design, with several integrated flexible workstations. Total length of the line is about 18mtrs.

Main Import Configuration:

1) MITSUBISHI HMI Display And PLC;

2) MITSUBISHI Frequency Converter;

3 )Japan NEMICON Inverter;

4 )Taiwan Hydromax Pump;

5) Taiwan High Temperature Resistant Tubing.

Basic Configuration:

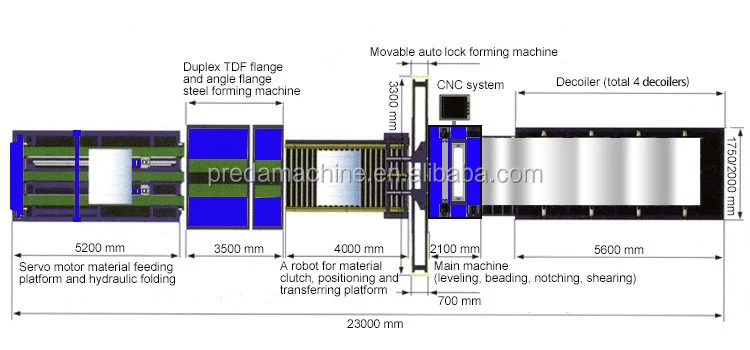

1. Two electric coil cradles, 4 material trays (5-7t each roll);

2. One rack;

3. One host (line 2 host);

4. One mechanical arm clutching, locating and transferring platform;

5. One displacement type locking machine;

6. One duplex TDF flange forming machine;

7. One duplex angle steel flange forming machine;

8. One servo feeding platform;

9. One hydraulic folding machine;

10. One set of computer controlling system.

Model | Sheeting thickness (mm) | Max width (mm) | Max working speed (m/min) | weight of coil (T) |

Dimension (mm) L*W*H |

Power (kw) |

Weight (T) |

AML-5-1300 | 0.5-1.2 | 1300 | 15 | 7 | 24000*3500*1500 | 30 | 12 |

AML-5-1500 | 0.5-1.2 | 1500 | 15 | 7 | 24000*4000*1500 | 30 | 13 |

More About Preda Machine Auto Duct Line 5

Preda Machine Auto Duct Line 5 , optimized linear structure makes the whole auto duct line beautiful in appearance and fast in production. Pneumatic manipulators push plate in conjunction with combined lock forming machine, high speed and positioning more accurate. Stepping out from traditional processing method, the auto duct line 5 saves time greatly and significantly improve production efficiency. Labor and time saver, high efficiency, a full piece of FULL rectangular duct can be finished in about 30 seconds. With production management functions: Day Count, Cumulative Count. Separate two kinds of input modes (touch screen and physical keyboard) ensure operation reliability greatly.

Preda auto duct line 5 is a multi-functional main body with a host duct line 2 ,one mechanical arm clutching, locating and transferring platform, one displacement type locking machine, one duplex TDF flange forming machine, one duplex angle steel flange forming machine, one servo feeding platform, o One hydraulic folding machine, one set of computer controlling system.It is controlled by a touchable computer controller for fully automated production.

Preda auto duct line 5 frame is made of high quality steel that has been cut, welded and polished. This has a strong tolerance. All the original accessories of the five lines are produced by Sweden and Germany. Strong wear resistance and long service life. All the main shafts and work rolls of theauto duct line 5 are thickened and widened, which also makes the forming degree better when processing the 1.2mm duct.

Preda auto duct line 5 have MITSUBISHI Display and PLC, MITSUBISHI Frequency Converter,Taiwan High Temperature Resistant Tubing,Taiwan high quality Pump and etc. Preda automatic duct line 5 can finish processing a whole roll of material to meet the dimensions of the production duct. It is labor and time saver, high efficiency.

When you want to change your production efficiency and look for an auto duct line 5 with high-efficiency production ducts, preda auto duct line will be your best choice.

The transport cost as reference please contact us to get more clearly transport cost directly. Different port of countries will have different cost!

FAQ

1. How to get a accurate quotation from Preda Machine?

Provide the machine name you want, the specifications you need and the quantity of machine, we shall quote accordingly!

2. What's the shipping cost from China to your country?

Please kindly tell us your nearest port to your place. We have reliable shipping forwarder to insure cheap, safe, convenient and timely delivery via sea.

3. Payment terms, MOQ, warranty, FOB.

Payment terms: 20% TT paid in advance, the balance of 80% before the shipment.

Minimum order quantity: 1 set of any machine of Preda Machine.

Delivery time : 5days after order confirmation. As a real manufacturer, we normally stock our machine in at least 5-10 sets including auto duct line 5, auto duct line 3, auto duct line 2!

And at least 20 sets each for TDF flange forming machine, Pittsburgh lock former, TDF folding machine, Pneumatic folder and etc...

Shipping terms : FOB, CFR, CIF and etc.. according to your requirements.

Warranty:24 months after our machines arriving at you.

4. What's the package?

Fumigation-free plywood case for LCL and nude package for full container basis such duct production line 5, duct auto line 3, duct line 2...

5. What about commissioning service?

We can offer commissioning service, the buyer need to pay for all the transport, salary, hotel, meals for Preda Machine technicians caused during the service period.

Old version auto duct production line 5 photos before Year 2015...

Related Machines