China factory sale auto duct production line 3 with low price automatic folding machine

China factory sale auto duct production line 3 with low price automatic folding machine

- Detail

- Review

- Parameters

China factory sale auto duct production line with low price automatic folding machine auto duct line 3

Product Description

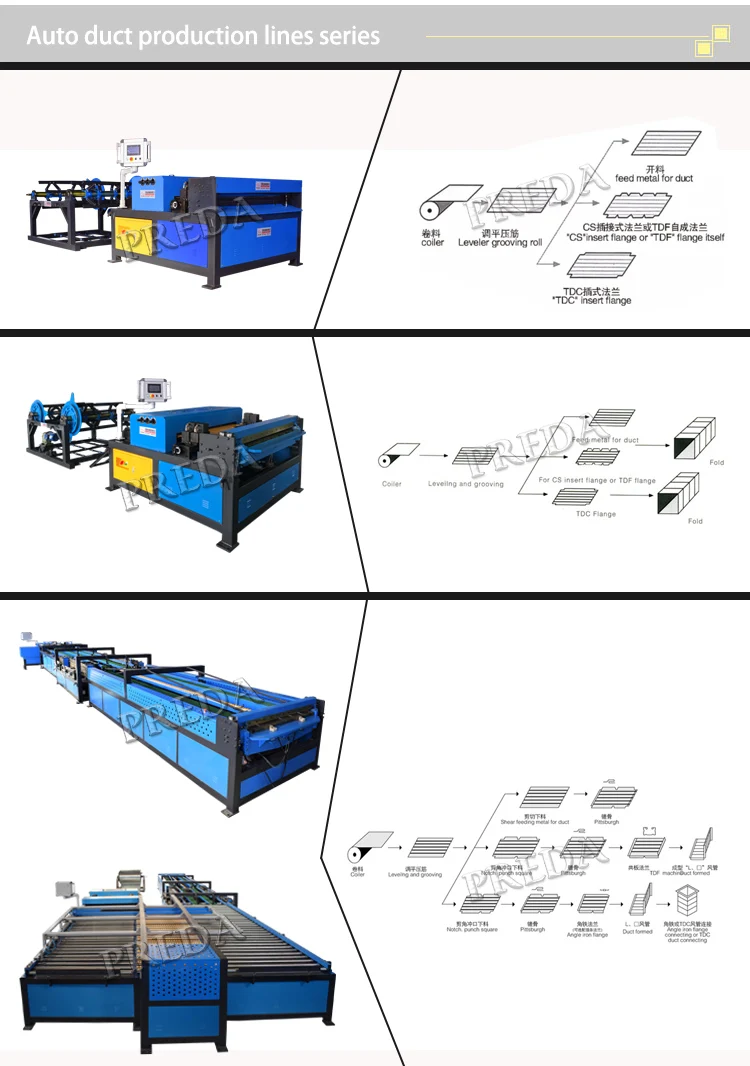

Preda auto duct line is a device for the production of rectangular ducts, whose automated production process replaces traditional manual manufacturing. The auto duct line 3 add an automatic folding function based on the auto duct line 2, which is mainly used to fold the "L" shape. Its structure is leveling, beading, notching (capable of sharp notching, TDF notching), plate shearing and plate folding.

Workstations and functions:

1.Electric double decoiler (2 sets of rollers) driven by independent frequency controlled motors.

2.Multi-functional main body with capability of leveling, beading, notching(capable of sharp notching, TDF notching) , plate shearing and plate folding.

3. Mitsubishi computer controlling system and software.

4. Mitsubishi and Siemens electric box and electrics.

Main Import Configuration:

1) MITSUBISHI Display and PLC.

2) MITSUBISHI Frequency Converter.

3) Taiwan High Temperature Resistant Tubing.

4) Taiwan high quality Pump.

Basic Configuration:

· Two electric coil cradles, 2 material trays (5-7 t each roll)

· One rack

· One host (duct line 2 host)

· One set of computer controlling system

Model | Thickness (mm) | Max width (mm) | Working speed (m/min) | Weight of coil (T) |

Dimension (mm) L*W*H |

Power (kw) |

Weight (T) |

AML-3-1300 | 0.5-1.2 | 1300 | 0-18 | 7 | 5000*1900*1500 | 9 | 4 |

AML-3-1500 | 0.5-1.2 | 1500 | 0-18 | 7 | 5000*2300*1500 | 11 | 4.5 |

More About Auto Duct Line III

Optimized linear structure makes the whole auto duct line beautiful in appearance and fast in production. There are five specifications for the auto duct line. They are auto duct line 2/ auto duct line 3/ auto duct line 4/ auto duct line 5/ u shape auto duct line 5. These auto duct lines are all manufactured by Preda Machine.

Preda auto duct line 3 is a multi-functional main body with capability of leveling, beading, notching(capable of sharp notching, TDF notching) , plate shearing and plate folding. It is controlled by a touchable computer controller for fully automated production.

Preda auto duct line 3 have MITSUBISHI Display and PLC, MITSUBISHI Frequency Converter,Taiwan High Temperature Resistant Tubing,Taiwan high quality Pump and etc. Preda auto duct line 3 can finish processing a whole roll of material to meet the dimensions of the production duct. It is labor and time saver, high efficiency.

Stepping out from traditional processing method, the auto duct line 3 saves time greatly and significantly improve production efficiency. The auto duct line is also one of the necessary equipment in the production of HVAC ducts. The automation is more popular with people.

When you are ready to upgrade your original small machine, Preda auto duct line 3 will be your best beginning. This is also the sign that you really realize the beginning of automated production.

Anhui Preda Machinery Manufacturing Co., LTD. is a manufacturing company. Our company is committed to the production of HVAC duct production machines. Our company has more than 10 years of production and export experience. Anhui Preda Machinery Manufacturing Co.,LTD is located in Hongyang Industrial Park, Bowang Town, Bowang District, Ma'anshan City, Anhui Province, China. It is only 20 kilometers away from Nanjing International Airport, which also facilitates customers from all over the world to come to our factory to have a convenient face-to-face conversation and visit.

We manufactured and exported auto duct lines, CNC plasma cutting machine, TDF flange forming machine, pittsburgh lock forming machine, spiral duct forming machine, elbow making machines, TDC flange forming machine, oval duct forming machine and so on. All our machines are popular in the ventilation pipe manufacturing industry. We also exported CNC hydraulic press brake machine, CNC hydraulic shearing machine with factory price and best quality. All of our duct machines are in stock, we will manufactured the most of standard commonly used machine as inventory, so if our customers need, we will arrange delivery all the time.

We also have our after-sale servie teams, we support our engineers overseas service. When you met the problems, we will help you solve the problem in time, and all the machines we will have a lifetime warranty. We use our sincerity to serve our customers and expect more customers to choose Anhui Preda Machinery Manufacturing Co., LTD.

Delivery details

Customers purchase our auto duct lines and we will ship them through containers.

The auto duct line 3 and the aut duct line 2 will be transported through the 20' container, and the auto duct line 5 and U-shape auto duct line will be transported through the 40' container.

CNC plasma cutting machine will also be transported through the 20' container.

All machines transported through the container are inside the container which we will pull the two sides of the machine with thick wire ropes and hooks so that they do not shake during shipping and cause the machine to collide.

A certain amount of movable space is reserved between the machine and the machine to ensure that the machine is intact when it reaches the customer's factory.

The packaging of small machines such as the duct TDF flange forming machine, the pittsburgh lock forming machine, and the elbow making machine will be packed in wooden cases.

The chassis is welded by channel steel and the bottom is reserved for 10cm for easy loading and unloading. It will be fixed with wooden boards around to avoid collisions during transportation.

1. How to get a accurate quotation from Preda Machine?

Provide the machine name you want, the specifications you need and the quantity of machine, we shall quote accordingly!

2. What's the shipping cost from China to your country?

Please kindly tell us your nearest port to your place. We have reliable shipping forwarder to insure cheap, safe, convenient and timely delivery via sea.

3. Payment terms, MOQ, warranty, FOB.

Payment terms: 20% TT paid in advance, the balance of 80% before the shipment.

Minimum order quantity: 1 set of any machine of Preda Machine.

Delivery time : 5days after order confirmation. As a real manufacturer, we normally stock our machine in at least 5-10 sets including auto duct line 5, auto duct line 3, auto duct line 2!

And at least 20 sets each for TDF flange forming machine, Pittsburgh lock former, TDF folding machine, Pneumatic folder and etc...

Shipping terms : FOB, CFR, CIF and etc.. according to your requirements.

Warranty:24 months after our machines arriving at you.

4. What's the package?

Fumigation-free plywood case for LCL and nude package for full container basis such duct production line 5, duct auto line 3, duct line 2...

5. What about commissioning service?

We can offer commissioning service, the buyer need to pay for all the transport, salary, hotel, meals for Preda Machine technicians caused during the service period.

6. What's policy for guarantee and broken parts?

Warranty period of equipment is two years, during which the broken parts and spares caused by quality can be offered free. After guarantee period, all broken parts or easy wearing parts will be charged in a most competitive price ever in the market!

Old version auto duct line 3 before 2015...

Basic Equipments,

1. Electric uncoiler(two sets) driven by independent frequency controlled motor.

2. Multi-functional machine with capability of levelling,grooving,angle shearing and plate shearing

3. Pnuematic folder

4. Computer controlling system and softwares.

5. Electric box

Characteristics,

1. Optimized linear structure makes the whole line beautiful in appearance and fast in production

2. 11 rollers are equipped for levelling to make sure plate gets even.

3. This machine is a material-saving facility with only less than 20mm wasted plates per roll.

4. Highly advanced servo system controls the whole production line very well so the products produced are perfect in appearance and precise in size.

5. One man is capable to handle the whole line

6. Workpieces counting system to count for one-day and accumulated quantities.

Specification,

| Model | Plate Thickness (mm) | Max. Plate Width (mm) | Speed (mm/min) | Weight (Kg) | Dimension (L×W×H, mm) |

| LINE III | 0.5-1.2 | 1300 | 16000 | 3000 | 3500×2500×1300 |

Related Machines

Duplex TDF Flange Forming Machine

To overcome the normal TDF flange forming machine’s disadvantage

that only one end of the plate can be operated to form flange,

duplex TDF flange forming machine provides a perfect solution for that.

Flange forming can be achieved for both ends at a time,

which makes the flanging process much more efficient and stable.

This machine is a top priority for companies who are short of staff

but desired for massive production.

TDF flange forming machine/TDF rollformer,

mainly used for making flange at edge of plate for further joint,

is also among basic equipments for modern duct forming line.

All bearings used are ball bearings rather than traditional

needle bearings so the machine more durable.

All gears, axles and rollers equipped in the machineare made from

high quality steel to ensure their stability and durability.

The flange shape made by the machine is nice and practical,

which makes it a perfect part of duct forming line.

Our TDF rollformer has two version, T-12 capable of 1.2mm

and T-15 capable of 1.5mm galvanized metal sheet.

This decoiler is specially designed for duct forming line to

make the material loading and transporting stable.

It can hold 5tons of coils.

Preda 7-function Lock former/Pittsburgh machines!

1. SA-12HB is capable of 1.2mm galvanized steel and SA-15B is

capable of 1.5mm.

Main difference between SA-12B and SA-15B is the rollers used.

2. To fulfil international customers' requirements on electrics standard.

We are able to change our motors and electrics

as per requested free of charge!!

3. 380V/50HZ/3PH is the regular standard for our machine.

Yet we can manage them into 220V/50HZ/1PH or 420V/50HZ/3PH...

Cost is free of charge as a cooperation to our international customers!!!

4. Lock shapes/pins for below,

1.Arc shape 2.Claw shape 3.Orthogonal shape 4.U shape 5. Union shape 6.Z shape 7. Lock pin

Preda Manual TDF Folding machine is specially designed for

HVAC duct folding process.

It can be used together with TDF Flange Forming machine and

Pittsburgh machine to make rectangular HVAC ducts!

Light weight and ease for operating/transport make it suitable

under many circumstances,

especially for short-term working at the construction site.

Machine produced with customerized length can be achieved.

To achieve higher production efficiency and less labor work,

pneumatic folding machine is a good alternative,

compared with manual TDF Folding Machine.

The operating principle is to use air cylinder to replace manual power

without even using electricity.

Rigid frame with strong steel welded is simple but nice.

Low electricity consuming and ease for operation make it widely

used for bending thick steel plate sheet.

It is capable to make 1 to 5 grooves with width adjustable for

customer's certain requirements.

Beading&slitting machine or groove&shear machine with

grooving and shearing function together,

specially designed for duct forming!

Just need to change the mould when you want to use its certain function.

Pneumatic corner matics for rectangular duct forming process!

Fixing one corner will take only about 6seconds!!

Hydraulic Guillotine

Hydraulic Guillotine

remarkable cutting quality and capacity in great cost performance

Rigid frame is built with thick concrete plate steel to ensure function

stability and durability.

Hydraulic powered system is to realize precise working power,

easy and safe operating.

Rake angle realized by a 0.5° to 3.5° tilt of the upper blade holder makes

the cutting more stable and enlarges the working capacity of thicker

steel plate.

Back gauge retracting range of 10mm-900mm satisfies customer’s common needs.

High mechanical strength and great rigidity is due to integrated

welded steel structure.

Hydraulic powered system is to realize precise working power,

easy and safe operating.

Simplified upper dies clamp with micro-adjustable wedges for high precision

Pre-installed upper dies with 88° angle andsolid block lower die with four

face multi “V” frame.