HVAC duct beading machine with auto duct line beader 1300mm and 2000mm square duct beader

HVAC duct beading machine with auto duct line beader 1300mm and 2000mm square duct beader

- Detail

- Review

- Parameters

Product Description

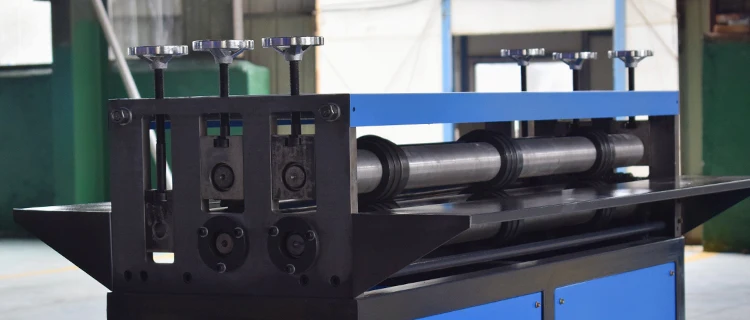

Duct Beading Machine is used to form beads on flat sheet metal for stiffening ductwork and fittings.

Beading rolls are designed for easy replacement if damaged and bead rolls are etched into the bead roll shaft for easy alignment.

Duct beading is a much faster practice as compared to the original cross breaking method.

A Duct Beading Machine is a fairly simple machine where in you feed flat sheet metal into the machine and the machine forms 5 beads on 1300mm width sheet or 7 beads on 2000mm!!(depending on the machine model).

Main Features

1) Handwheels can be adjusted up and down, so that control the depth of the hook groove.

2) Suitable for 0.4-1.2mm galvanized steel coil, can be successful at one time.

3) Only one person can operate, it don't need a lot of people to operate.

4) The machine is widely used, and one machine can be used for many years.

| Model | Thickness (mm) | Max width (mm) | Power (kw) | Weight (kg) | Dimension L*W*H (mm) |

| G1.2*1300 | 0.5-1.2 | 1300 | 1.5 | 500 | 1550*900*1060 |

| G1.2*2000 | 0.5-1.2 | 2000 | 2.2 | 650 | 2300*900*1120 |

More About Preda Machine Duct Beading Machine

Preda Duct Deading Machine is also named Duct Grooving Machine. It is used for making 5/7 line grooves with depth for prodcution HVAC duct in strengthen the air duct.

Preda Deading Machine has 6 handwheels for adjusting up and down in making grooving depth. Grooving machine has 2.2 kw power, it is suitable for 0.4-1.2mm galvanized steel, and can be successful at one time! Preda beading machines' standard voltage is 380v/220v, but we can still meet the voltage requirements of different countries. Preda beading wheels are made high quality steel, after lots of processing techniques, it is then quenched to increase its hardness, it makes work well.

Preda beading machine is in duct making machines with a very high cost performance, which is very popular among European and American countries, and our price is very affordable.So it is a best choice when you plan to purchase a duct grooving machine/duct deading machine.

Anhui Preda Machinery Manufacturing Co., LTD. is a manufacturing company. Our company is committed to the production of HVAC duct production machines. Our company has more than 10 years of production and export experience. Anhui Preda Machinery Manufacturing Co.,LTD is located in Hongyang Industrial Park, Bowang Town, Bowang District, Ma'anshan City, Anhui Province, China. It is only 20 kilometers away from Nanjing International Airport, which also facilitates customers from all over the world to come to our factory to have a convenient face-to-face conversation and visit.

We manufactured and exported auto duct lines, CNC plasma cutting machine, TDF flange forming machine, pittsburgh lock forming machine, spiral duct forming machine, elbow making machines, TDC flange forming machine, oval duct forming machine and so on. All our machines are popular in the ventilation pipe manufacturing industry. We also exported CNC hydraulic press brake machine, CNC hydraulic shearing machine with factory price and best quality. All of our duct machines are in stock, we will manufactured the most of standard commonly used machine as inventory, so if our customers need, we will arrange delivery all the time.

We also have our after-sale servie teams, we support our engineers overseas service. When you met the problems, we will help you solve the problem in time, and all the machines we will have a lifetime warranty. We use our sincerity to serve our customers and expect more customers to choose Anhui Preda Machinery Manufacturing Co., LTD.

Delivery details

Customers purchase our auto duct lines and we will ship them through containers. The auto duct line 3 and the aut duct line 2 will be transported through the 20' container, and the auto duct line 5 and U-shape auto duct line will be transported through the 40' container. CNC plasma cutting machine will also be transported through the 20' container. All machines transported through the container are inside the container which we will pull the two sides of the machine with thick wire ropes and hooks so that they do not shake during shipping and cause the machine to collide. A certain amount of movable space is reserved between the machine and the machine to ensure that the machine is intact when it reaches the customer's factory.

The packaging of small machines such as the duct TDF flange forming machine, the pittsburgh lock forming machine, and the elbow making machine will be packed in wooden cases. The chassis is welded by channel steel and the bottom is reserved for 10cm for easy loading and unloading. It will be fixed with wooden boards around to avoid collisions during transportation.

1. How to get a accurate quotation from Preda Machine?

Provide the machine name you want, the specifications you need and the quantity of machine, we shall quote accordingly!

2. What's the shipping cost from China to your country?

Please kindly tell us your nearest port to your place. We have reliable shipping forwarder to insure cheap, safe, convenient and timely delivery via sea.

3. Payment terms, MOQ, warranty, FOB.

Payment terms: 20% TT paid in advance, the balance of 80% before the shipment.

Minimum order quantity: 1 set of any machine of Preda Machine.

Delivery time : 5days after order confirmation. As a real manufacturer, we normally stock our machine in at least 5-10 sets including auto duct line 5, auto duct line 3, auto duct line 2!

And at least 20 sets each for TDF flange forming machine, Pittsburgh lock former, TDF folding machine, Pneumatic folder and etc...

Shipping terms : FOB, CFR, CIF and etc.. according to your requirements.

Warranty:24 months after our machines arriving at you.

4. What's the package?

Fumigation-free plywood case for LCL and nude package for full container basis such duct production line 5, duct auto line 3, duct line 2...

5. What about commissioning service?

We can offer commissioning service, the buyer need to pay for all the transport, salary, hotel, meals for Preda Machine technicians caused during the service period.

6. What's policy for guarantee and broken parts?

Warranty period of equipment is two years, during which the broken parts and spares caused by quality can be offered free. After guarantee period, all broken parts or easy wearing parts will be charged in a most competitive price ever in the market!

Beading Machine/Groover for 5 grooves

Brief Introduction,

It is capable to make 1 to 5 grooves with width adjustable for customer‘s certain requirements.

Specification,

| Model | Plate Thickness (mm) | Max. Plate Width (mm) | Power (Kw) | Weight (Kg) | Dimension (L×W×H, mm) |

| JXP-1300 | 0.5-1.2 | 1300 | 2.2 | 1300 | 1540×1270×1100 |